Why should you choose Crown Norge & LKH Tools?

Our high quality, Swiss manufactured tooling for all types of routing machines, are renowned for exceptional cut quality, longevity and performance in a variety of materials. We also provides technical assistance on the correct choice and use of the tooling along with training, software and application support to customers in a variety of applications and industries. LKH Tools slogan “Taking the guesswork out of CNC routing” is backed up with over 25 years of experience in the industry while Crown Norge defines “Innovative cutting tools” as its company Moto. This has certainly been the case as a number of industries first’s came from Crown Norge. Unique coatings, considered dimensions and balanced tooling (for high speed spindles) to name but a few.

The Crown Norge tools are manufactured to an incredibly high standard using the highest grade European carbide. In addition to this, the machines used to manufacture them are regularly inspected, tested and updated to ensure these consistent standards are met for each tool produced. The grinding wheel is assessed at regular intervals and adjusted accordingly by experienced and highly skilled operators. The tools are individually inspected prior to approval, ensuring these high standards are met consistently.

The additional care and attention given to each tool is reflected in the final result. This disciplined approach to manufacturing of the tool, ensures the operator has the confidence to use the same settings from the first tool to the last. Removing the need to adjust the machining perimeters due to tooling differences. With higher than ever sheet material costs, it is critical to get it right first time, every time. Any slight variances in the routing tool could result in re-cutting of the job and scrapping a sheet of expensive material. The higher cut quality, tool longevity and performance of these tools is highlighted even further when comparing the overall total economy. The Crown Norge tools from LKH Tools, are the best value for money.

Polishing clear acrylic

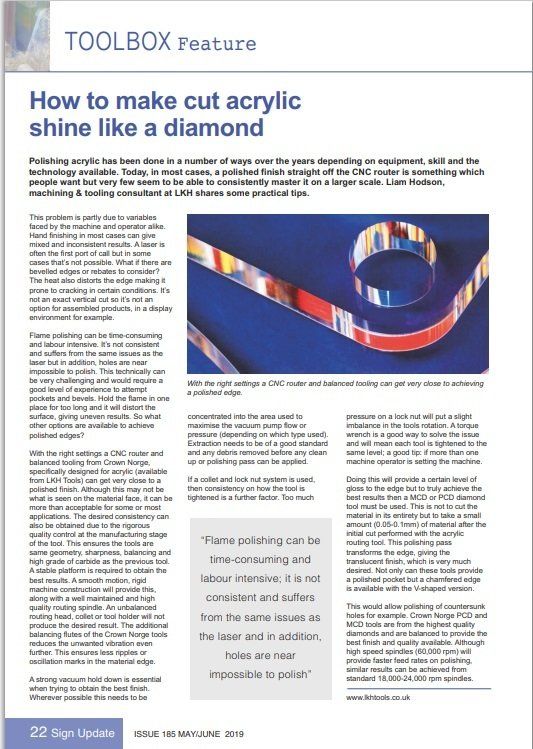

Meeting the demand for highly polished clear acrylic, the PCD, MCD and MCVD diamond polishing tools are are also available in addition to the standard carbide and coated carbide tools.

Available in a variety of diameters and length’s, these are to be used as a secondary pass to remove 0.05-0.1mm of material leaving a polished and clear edge for up to 30mm thick material.

This will produce vertical edges and with no heat to distort the material, they are ideal for applications where curves, intricate shapes, joints and stepped profiles are also required to be polished. In conjunction with the straight polishing tools, a bevelling polishing tool allows for polished countersunk holes or to chamfer the edge of the material to remove sharpness for handling. The polishing tools perform at their best on a rigid machine, with a good vacuum hold down. Any vibrations from the material moving or machine flex will be shown in the edge of the material.

(PCD = Polycrystalline Diamond)

(MCD = MonoCrystalline Diamond)

(MCVD = Chemical Vapour Deposition Diamond

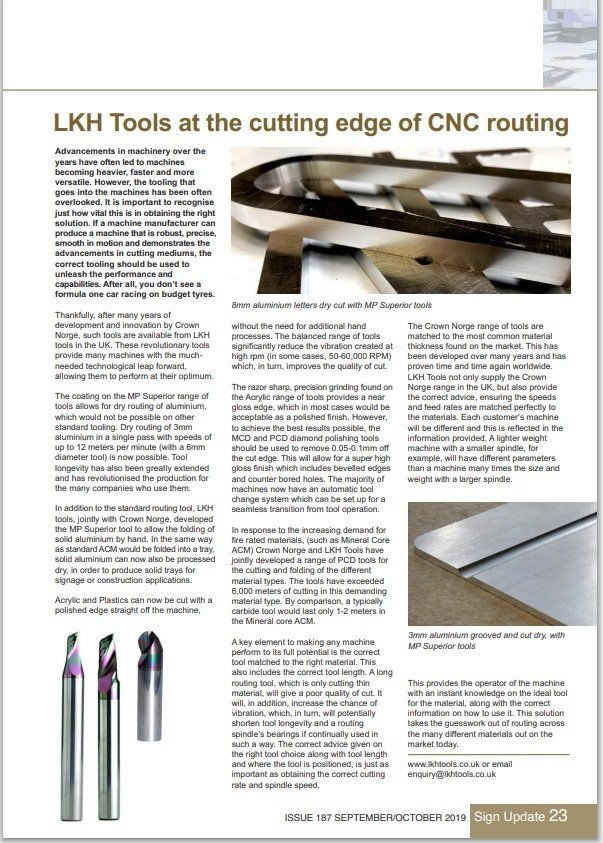

The unique coating on the MP Superior range of tools was first introduced in 2018 and is still the best option for high speed, dry routing of aluminium and other non-ferrous metals today.

The available sizes in the range have been increased from the initial launch in 2018. Sizes are now available from 2mm to 10mm diameters and also with greater options for up to 50mm thick materials. The MP Superior tools run faster, last longer and produce an exceptional quality of cut without the need for coolant or oil.

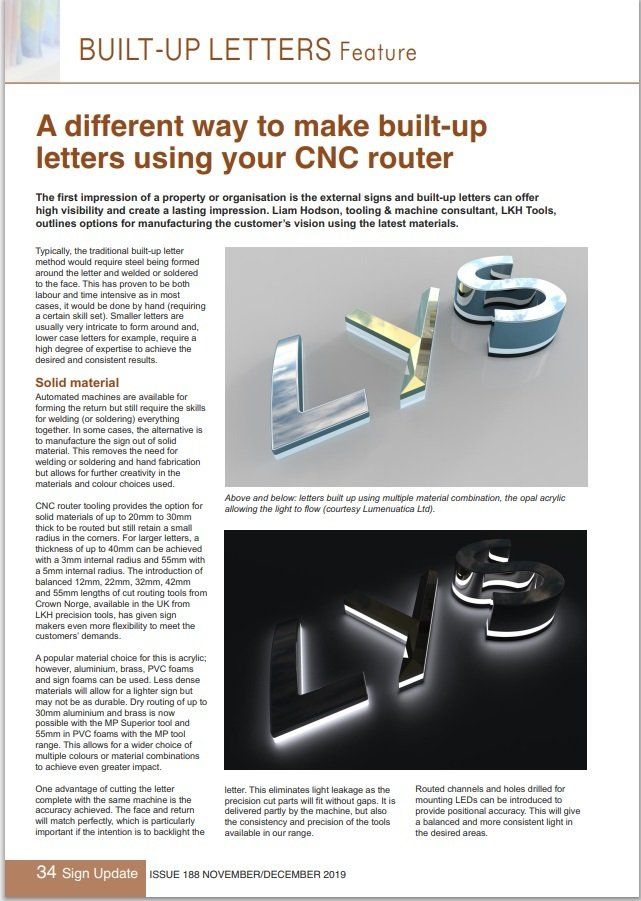

The acrylic GEN2 (Generation2) range of tools are a relatively new alternative to achieve polished results in clear acrylic. Available in 3mm, 4mm and 6mm diameters, they are ideal for applications such as a smaller production run or where the slightly higher degree of polished edge from a diamond polishing tool is not warranted. These carbide tools are ground specifically to provide the best edge possible in clear acrylic. Additional grinding time during the manufacturing process and specific cutting angles on the helix of the tool, produce a polished edge in a single cut and without the need for a secondary clean up pass. The GEN2 tool can also be used in other clear materials such as polycarbonates, a material very difficult to normally produce a polished edge on.

Customers who have the option for higher rotation speeds (such as 30,000-60,000 RPM) benefit from the specific range of tools available for these higher spindle speeds. Additional balancing in the tool design produces a improved cut surface finish and smoother rotation of the tool. At high rotation speeds, any imperfection in the balancing of the tool can lead to excessive vibration, poor quality of cut, tool wear and in extreme cases, premature spindle failure.

Get it right first time, every time....

With different machine type, tool and material combinations available, getting the best results first time can be a challenge. LKH Tools provides the customer with the correct machine cutting parameters to accompany the correct tool choice. This can also be optimised based on the customers requirements, machine and material specifics. This reduces any costly mistakes potentially made by the end user and the trial and error process often machine operators have to go through. Utilising the onsite CNC routing machine at LKH Tools allows for testing of new materials, tool designs and optimisation for the customer. Difficult to cut and new materials can be sent to LKH Tools for testing. The correct tool and machine parameters are then provided back to the customer. Machine operators and customers which are new to CNC routing also get a big leap forward on the learning curve with assistance and advice available, provided by telephone, online or onsite. When using the correct tool and settings, the cut quality and production time dramatically improves. In addition, it will also reduce or eliminate any labour intensive hand finishing afterwards.

With all the common sizes and dimensions of router tooling stocked at the UK office in Nottingham, LKH Tools offers next working day delivery. This is invaluable for meeting tight deadlines when production has come to stand still due to unforeseen circumstances. Customers also have the option to collect in person. This also allows them to visit the showroom for advice, inspiration and to fine tuning and expand their CNC routing knowledge.